СБ 10:00—15.00, ВС.- вх

We manufacture equipment for all modern extraction methods:

Traditionally, the resin of the plant was extracted from the inflorescences mechanically:

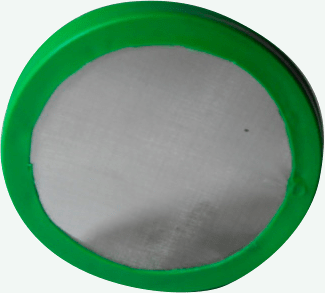

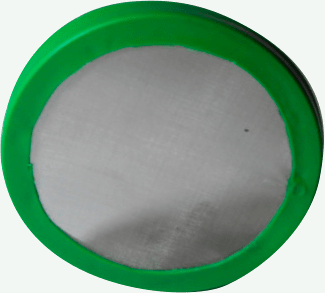

1) by sifting through a sieve, the dried inflorescences breaking off from the surface, to "knock out" the resin from the flowers, followed by their molding into "bricks".

2) Or in a rougher way - when you roll the sticky tops between your palms, and then scrape off the resin from them.

On a global scale, the dry screening method is much more common, a significant part of it is dry screened. However, the countries where historically the "handbrake" was mainly made; and today considerable quantities are rolled by hand.

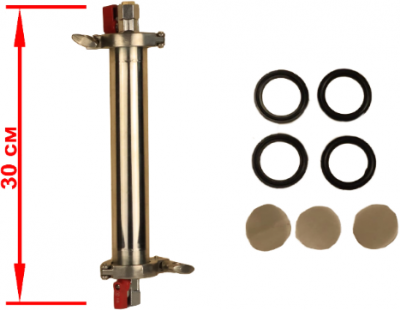

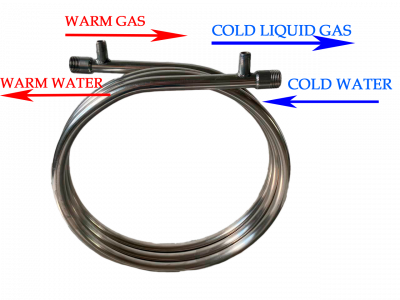

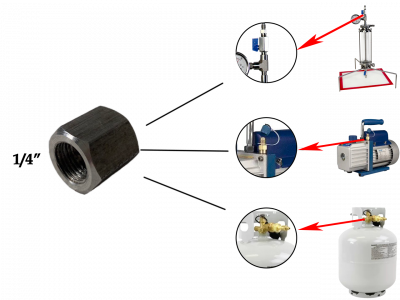

In the last few decades, new technologies for extracting resin from plants have appeared, in which a minimum of inert green mass enters the final product. Basically, these are chemical methods, such as the use of butane gas or CO2 extractors. These extracts are often phenomenally psychoactive. Many samples contain up to 90% of the active substance. For comparison, traditional technologies make it possible to obtain a product with a content of 15-40% of the active substance.

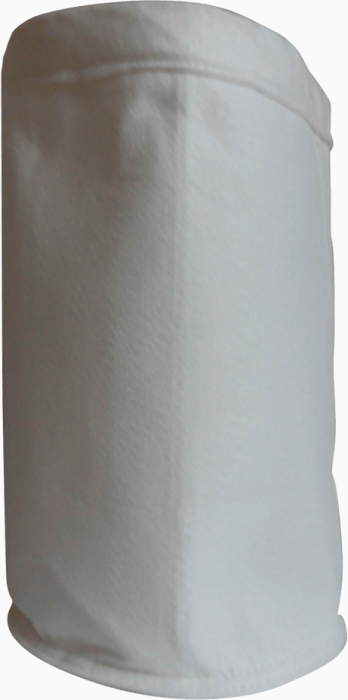

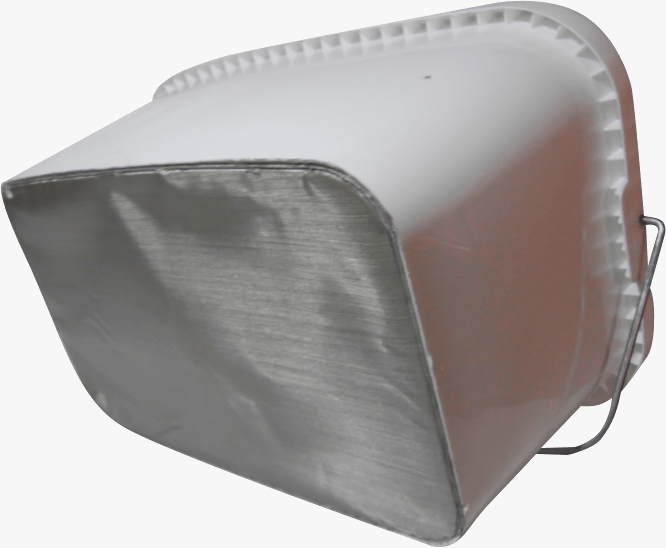

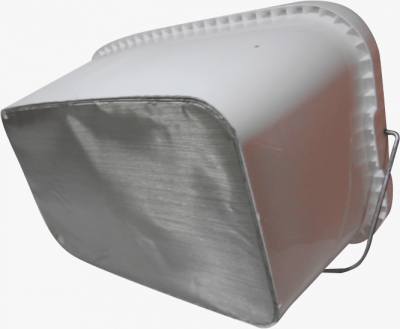

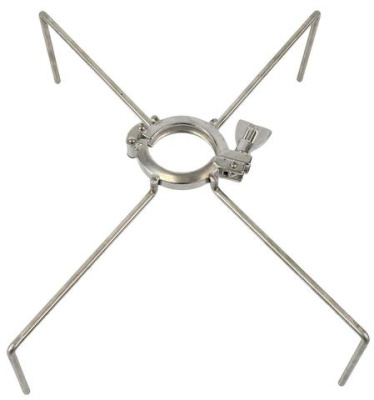

Another extraction method is the extraction of THC in ice water. The essence of this method is that the flowers are immersed in water with ice, where the substance solidifies, becomes brittle, and when stirred, separates from the surface of the flowers. In this sense, the method is mechanical. However, water plays a much larger role here than just freezing. Extraction in ice water can be done in a variety of ways, often with expensive equipment, but a simple bucket of ice water and a hand mixer will also work. Using this method, it is easy to understand how the separation of the active substance from the plant mass occurs: it is much heavier, therefore it sinks to the bottom of the bucket, while the flowers and leaves remain on the surface.