Купить наборы пластиковых контейнеров с металлическими сетками для экстрагирования сухим льдом

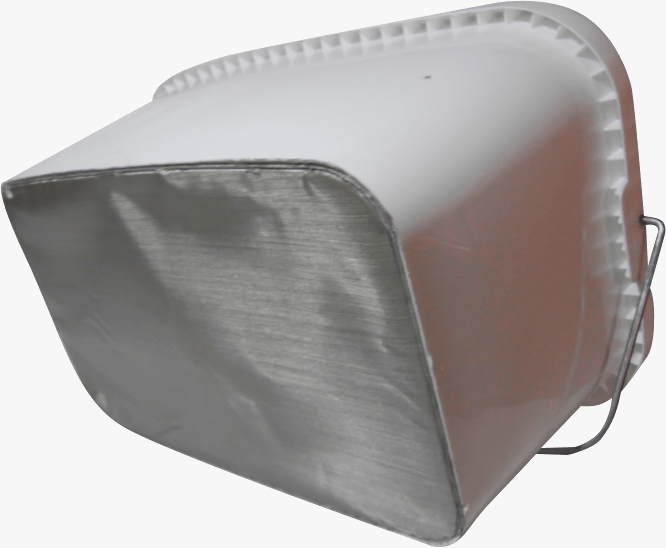

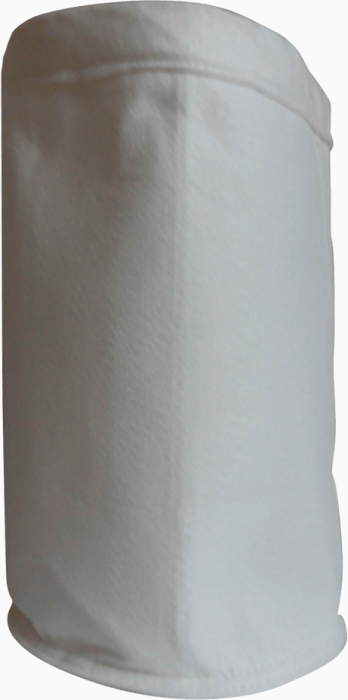

We produce special equipment for the extraction of vegetable raw materials by dry ice protrusion. It helps to shake out, knock out the most valuable thing!! To any set, the micronization of the mesh bucket is of your choice. Bucket capacity 3.3 l., 5.8 l. and 11 l. If you have sets, then you can buy the missing ones in the categorycontainers for dry ice extraction by the piece

We will help you make money on expenses and get rid of the garbage: stick-stems, semak, foliage, inflorescences=the most valuable thing. Awesome-necessary thing, both for a huge amount and for a small zhmenka)

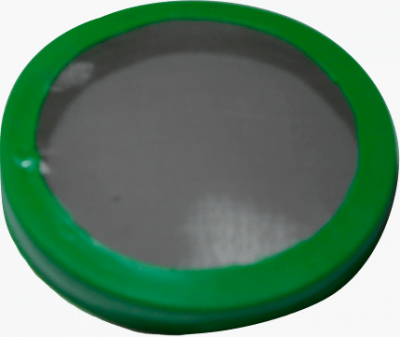

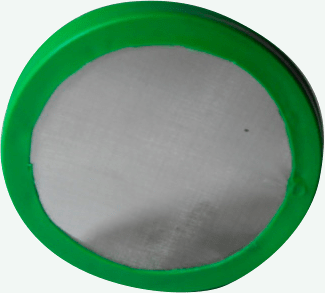

For extraction with dry ice, it is necessary to beat the raw material against a solid wall, a mesh cover, and carefully fold everything of value into a special compartment. Also, according to your desire, a lid-huller of seeds is purchased for any set, it is also a grinder of leaves and inflorescences for better knocking out of dust, which is very firmly attached.

You can also perform ice extraction by filling buckets with ice water. Working with a mixer, you will get the opportunity to filter the water. Filter product from 20-150 microns (18 microns filter must be purchased).

All parts are sealed and tightly closed with lids for super shaking.

All meshes are stainless steel.

Bucket capacity 3.3 l., 5.8 l., 11 l.

Dry ice extraction technique:

1. First of all, we take the container with the smallest sieve. We fill it with raw materials and dry ice, the amount should not exceed 30% of the volume of our container. Then we place the sieve container in a container with a bottom, tightly close the lid. Now you need to create a good SHAKE. We shake strongly, intensively with a large amplitude so that the raw material with ice beats as hard as possible and more often against the walls and the grid, then we get the BEST result. SHAKING is the most important, it is necessary to understand that it depends on the quantity and quality of products. After all the best came out, we got 1 fraction from 0-70 microns.

2. We pour the remaining raw materials from the first container into a sieve container with large cells. We repeat the shaking process, as described in paragraph 1. After shaking in a container with a bottom, we got the production of 2 fractions from 70 to 100 microns.

3. The last stage of dry extraction. All that remains from the second sieve container we pour into a sieve with large cells. We also repeat the shaking process as described in paragraph 1. At the end we get 3 fractions from 100 to 150 microns.

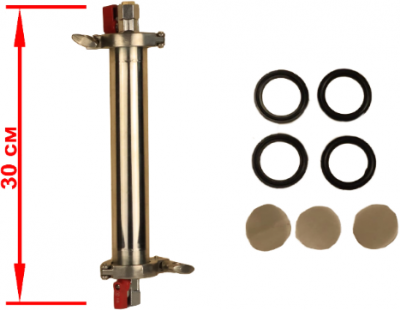

After all the dry extraction processes described above, we again have raw materials left, which some call garbage and simply throw away. We suggest you use a butane extractor. Which will help to extract valuable components from the "garbage".

https://greenpower.in.ua/poshtuchno-konteynery-s-metallicheskimi-setkami/

| Image | Name | Price | Qty | |

|---|---|---|---|---|

|

container assembler (5,8 литров) | 120 грн. | 1 | |

|

Lid for container (5,8 литров) | 30 грн. | 1 |

| Image | Name | Price | Qty | |

|---|---|---|---|---|

|

container assembler (3,3 литра) | 80 грн. | 1 | |

|

Lid for container (3,3 литра) | 25 грн. | 1 |

| Image | Name | Price | Qty | |

|---|---|---|---|---|

|

container assembler (5,8 литров) | 120 грн. | 1 | |

|

Lid for container (5,8 литров) | 30 грн. | 1 |

| Image | Name | Price | Qty | |

|---|---|---|---|---|

|

container assembler (3,3 литра) | 80 грн. | 1 | |

|

Lid for container (3,3 литра) | 25 грн. | 1 |

| Image | Name | Price | Qty | |

|---|---|---|---|---|

|

container assembler (5,8 литров) | 120 грн. | 1 | |

|

Lid for container (5,8 литров) | 30 грн. | 1 |

| Image | Name | Price | Qty | |

|---|---|---|---|---|

|

container assembler (3,3 литра) | 80 грн. | 1 | |

|

Lid for container (3,3 литра) | 25 грн. | 1 |

| Image | Name | Price | Qty | |

|---|---|---|---|---|

|

container assembler (11 литров) | 180 грн. | 1 | |

|

Seed huller container (11 литров) | 480 грн. | 1 |

| Image | Name | Price | Qty | |

|---|---|---|---|---|

|

container assembler (11 литров) | 180 грн. | 1 | |

|

Lid for container (11 литров) | 40 грн. | 1 |

| Image | Name | Price | Qty | |

|---|---|---|---|---|

|

container assembler (5,8 литров) | 120 грн. | 1 | |

|

Seed huller container (5,8 литров) | 336 грн. | 1 |

| Image | Name | Price | Qty | |

|---|---|---|---|---|

|

container assembler (11 литров) | 180 грн. | 1 | |

|

Lid for container (11 литров) | 40 грн. | 1 |

| Image | Name | Price | Qty | |

|---|---|---|---|---|

|

container assembler (3,3 литра) | 80 грн. | 1 | |

|

Seed huller container (3,3 литра) | 248 грн. | 1 |

| Image | Name | Price | Qty | |

|---|---|---|---|---|

|

container assembler (11 литров) | 180 грн. | 1 | |

|

Lid for container (11 литров) | 40 грн. | 1 |